This week we had the honor to interview George Sun, CEO of Nextiles, a material science company working on next generation flexible wearables.

Nextiles built a smart apparel platform that helps people exercise better, more safely, and more efficiently. The company pairs athletic apparel with an analytics system that identifies new insights about a persons movement.

The company weaves and threads electrically conductive fibers to develop new types of wearable circuitry, through a repurposed sewing technology. The company has an expertise in electrical engineering and circuit design, giving the unique ability to merge fabrics and hardware to engineer new wearable platforms. Nextiles was founded on 2019 and is headquartered in New York, New York.

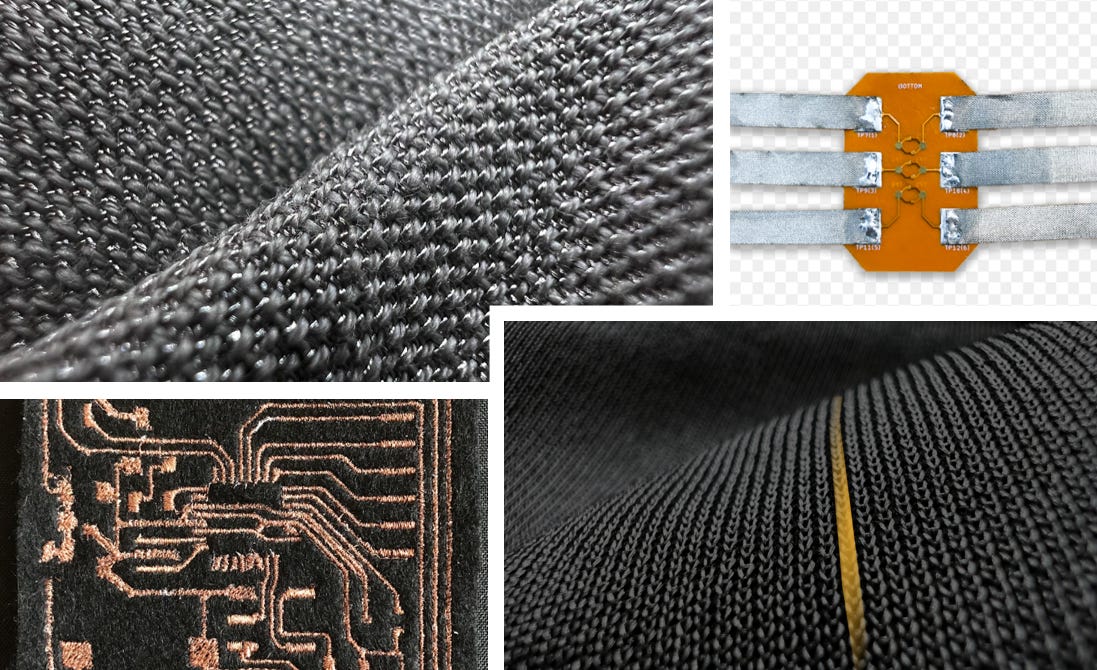

Here are some pictures of Nextiles’ sensors embedded into the fabric:

Picture: Nextiles

Here are some pictures of Nextiles’ next generation flexible wearables:

Picture: Nextiles

Here is a video illustration Nextiles’ product and vision:

Video: Nextiles

📝Show Notes: Through this interview, we touched on his background, his company, product, his view on the smart clothing market, his business model. We also talked about how his product benefits the teams. Then we discussed his plans for the next 12 months.

🚀Best Quotes: Here’s some of the key discussion points and best quotes from our conversation with George:

On his background:

“So my whole background has been focused on academics and research. What that meant is that I did my bachelor degree in electrical engineering and computer science, as well as bioengineering at UC Berkeley. That work was incredibly theoretical. You just study books and you had some hands on work, but it was until after my bachelor that I decided to do a PhD and for my PhD, I shifted more towards hands on science. And that was in material science. So I did that at MIT and while at MIT I had the privilege to connect with industries that were interested in my work”.

“That got me recognized by institutions like Puma. And so I worked with Puma and this is where I was working on their embedded systems making new shoes, new foams, new designs, and especially on the wearable side where I worked on how to integrate electronics into fabric”.

On how he started his company Nextiles:

“After that I was exposed to how quickly you can translate the scientific world into a product and this is when I realized that I had some of that capabilities on my own and wanted to do my own company”.

“So I was living in Germany, and I got invited to work in New York, particularly in the garment district, the fashion district and an area which is right here called the Brooklyn Navy yard where we specialize in advanced manufacturing and one of our headquarters is in the new lab”.

“We have 3D printers and sewing machines. And all that being said, this combination of academics and working in an environment in New York is really receptive to advanced manufacturing. That's where we built Nextiles which is focusing on soft goods, fabrics, and wearable sensors”.

On their targeted markets and GTM strategy:

“We are a B2B2C company, meaning that we build the materials, the sensors and we leverage that IP for other companies. So you can imagine that we can work with the Puma and Nike of the world, but we've also decided to work with institutions like the NBA, baseball players, and tennis players”.

On the fact that half of its team is software focused:

“The other side of that is that we are also a data company and with our materials, sensors, we also provide software. So half of our team is software focused, which is a unique hybrid to most hardware based companies”.

“We not only provide the hardware and the soft goods, but in addition, we provide the software capabilities of machine learning, data allocation, data encryption, and so on”.

“So we provide those insights and the analytics to the professional sports world, but you can imagine as we gain more traction, more intelligence on the machine learning side, on the server side, we can take that knowledge from the best of the best, and what makes the best players, and how they are excelling technique wise, and how they are preventing injuries, and then use that knowledge for the consumers, the amateur sports, and finally we can take that knowledge to go into the medicine space. Also maybe it is a little too early to explain now, but we also have some contracts with the Air Force”.

On the work they are doing in terms of integrating sensors into the fabric:

“We fully integrate sensors into the fabric. So what that means is that we can do the biomechanics and then biometrics. So concretely we're able to sew conductive threads, which have the ability to transfer electricity and electrons from one end to the next”.

“That's useful because you can think of them as neurons. There are ways to transfer information from one part of a garment to the next part of the garment. We call that biomechanical because that transfer is dependent on any kind of mechanical distortion. So you can imagine as I'm moving around and my clothes are wrinkling, they're tightening, they're bending, they're stretching because that signal's traveling through”.

“So these changes in the garment, and we could actually track those changes and say, Hey, when we received that signal, it changed by 20%, or by 30%, or it looked a little bit different. We can then map that back to what caused that change. Just because you bent the arm, you've twisted the fabric and you've pulled on the fabric because you bent backwards or you kicked a ball”.

On how its solution can precisely track body motion, join angles of an elbow, and much more:

“So all that information is captured directly to the fabric. And so the reason why we call it bot mechanical is because we can measure extremely precisely the body motion, the joint angles of an elbow, the joint angle of the knee, the amount of force you're putting on your foot to the twisting or torqueing of the shoulder”.

“And we do that by providing platforms that focus on those types of information on the body. So we made compression sleeves for the elbow and the shoulder (..) These are all white labelable products that we have. And we are a B2B2C company so that if you want to have it in a different color, a different fabric, we can do that for you”.

On the types of biometric/biosensing capabilities that they can track:

“On the biometric side of things we can provide things like the heart rate or muscle activity. And those you can also do with the fabric. I can't disclose too much publicly as of now, but there are ways to use fabrics, conductive fabrics as a way to measure things like skin voltage or temperature, or even possibly sweat”.

On their focus on publishing scientific studies and building various algorithms tailored to different sports:

“So for us, we are in the world of publishing and creating white papers. We do validation studies with universities. And we show them how we analyze our data. And it's because I don't necessarily come from a sports background. I come from a scientific background where things are peer reviewed. So I definitely have an urge and our company has kind of a thesis of sharing data and making sure these algorithms are correct. But to answer your point we do build algorithms per sports vertical”.

“So even though you may be wearing a sleeve for golf, or you may be wearing a sleeve for tennis, the analysis is different for both of them. In the future, though, if there are enough people that wear this and we see a world where people will, you can use machine learning to tease that out”.

“So you don't need to tell me that you're playing golf. The machine will recognize that signature because from our data sets as a human, I can actually decipher whether it was a golf swing or a tennis swing. That's how dramatic the forms are when it comes to our sensors. Obviously the machine takes some time to train and we don't have enough data yet, but visually if I can tell a machine can tell so this is the future that we envision”.

On the key benefits provided by its product to the teams:

“I can break that down to the two segments, the hardware and the software. The why we're different on the hardware is basically that we provide machine washable platforms. Now they're fitable because we create them in different sizes. It's all human oriented. When it comes to the wearables it's humans first. We're not trying to retrofit a pod into a watch. We're not trying to make a circuit board strap to your chest. And we build that through things that we're familiar with, which is clothing. So again, machine washing to the ability to buy different sizes for it, to be comfortable and fit, to have moisture wicking, all these properties you would find and an outlet store, we provide that in our hardware”.

“We're not here to be a gimmicky device. We're not here to congratulate you because you did 10,000 steps. We're here to tell you that there are ways to perfect your form and also to prevent injuries. And to do that, we call those longitudinal studies. You know, we're not here to give you a quick endorphin like “congratulations, you stood up for 12 hours a day”.

“We are going to tell you that historically after 12 months or 12 weeks to 12 days, are you improving or are you not improving? And can we suggest ways to be better? And that's why I love working with our partners. They are the experts in their fields, physical therapists, the sport scientists, the data scientists that we are learning from them to then teach our algorithms, our machines to be complimentary to them and to support their insights. And for the software, it's just about being extremely precise. ”

On their business model:

“So for the hardware, you buy it, and therefore you own it. And if you want to buy replacements, you can always buy replacements, but for the software because we are more of an engine we're more of the analytical power to the apps, websites, or to someone's AMS system, so to enable that we do provide a software development kit (SDK)”.

“This is a package you can download. You could consider it as a Google maps where you could see maps on restaurants as a map on Yelp. They can take packages from Google maps and insert it. So our SDK is something that you can download’.

“It's licensable so there is either a monthly or yearly fee associated to having the power of the Nextiles SDK and what the SDK does for you is do the computations and these computations aren't done on our servers. These are through APIs. So whether you want to analyze torque, create a report, find historical data of an athlete, those are done through APIs, which are available for a fee”.

“There is also a per user per month fee. So for every user using our SDK that's on the platform. Let's say through the NBA or through the NFL, their users or through the business themselves, they do have to pay payment plans for working with us. It could be negotiable. We do have some flat structures, but overall that's kind of the two worlds we live in a normal hardware sale and a SaaS stream through our software platform”.

On their plan for the next 12 months:

“So the plans for the hardware scaling is that we are in a way perfecting the method of making conductive and flexible sensors in fabric. So when it comes to scaling up, we have a phenomenal manufacturing site in New Jersey. We have another one that's a little bit smaller in Brooklyn, New York. We can pump out a few thousand a week. We can definitely service the customers we have today, but obviously we want to scale to hundreds of thousands to millions. So scaling our resources, finding the right partners is why we want do the hardware side”.

“And that will take 12 months to iron up the supply chain and the logistics. But in terms of the R&D we're very happy that our patents are solid. Our machines and equipment are great, and we have a phenomenal team that has a skillset to further optimize the hardware. On the software side we want to get more data and begin to create these algorithms. To do that we are working with third party institutions. They could be universities, or other agencies to prove to people that we are valid against gold standards. It could be an existing wearable. It can be camera vision. It can be just a medical professional approving that the data is working for their system”.

“So in the next 12 months on the software side, I can say that it's more about developing those algorithms and validating them so that when those happen and we continuously to gain credibility in the market, we can then use the scaled hardware side to start delivering the hardware to people who now see value in the product”.

On the products that they are selling and shipping today:

“Right now we're delivering our products. And we have enough insights. We have enough value in the software that we are beginning to sell our compression sleeve in particular to athletes. So you can be playing golf, baseball, basketball, as long as you're using your arms, we do a really good job of measuring the mechanics of the elbow and shoulder”.

“And we also have another sister product for the knee. So for those who are doing squats or weight lifting that's what we are selling now, but obviously when it comes to scaling the bigger companies, those who work at the league level, those who work at training facilities, we want to scale for them and, and that'll take a few months, and then we believe by 2023, and I can't disclose this for now, but we do have other products of the pipeline, so things like socks. By 2023, we'll have a bigger portfolio of products to provide”.

You may also like:

🔥 Upside Chat: Dave Hancock, CEO, Apollo (Leading Athlete Management Systems (AMS) vendor)

🔥Upside Chat: Alexi Pianosi, Strengths and Conditioning Coach, Pittsburgh Penguins (NHL)

🔥Upside Chat: Pierre Barrieu, High Performance Director, Toronto FC (MLS)

Share this post