Today we have the honor of interviewing Kevin Wu, Co-founder & Chief Business Officer at Fitasy, a leading Personalized 3D Printed footwear company.

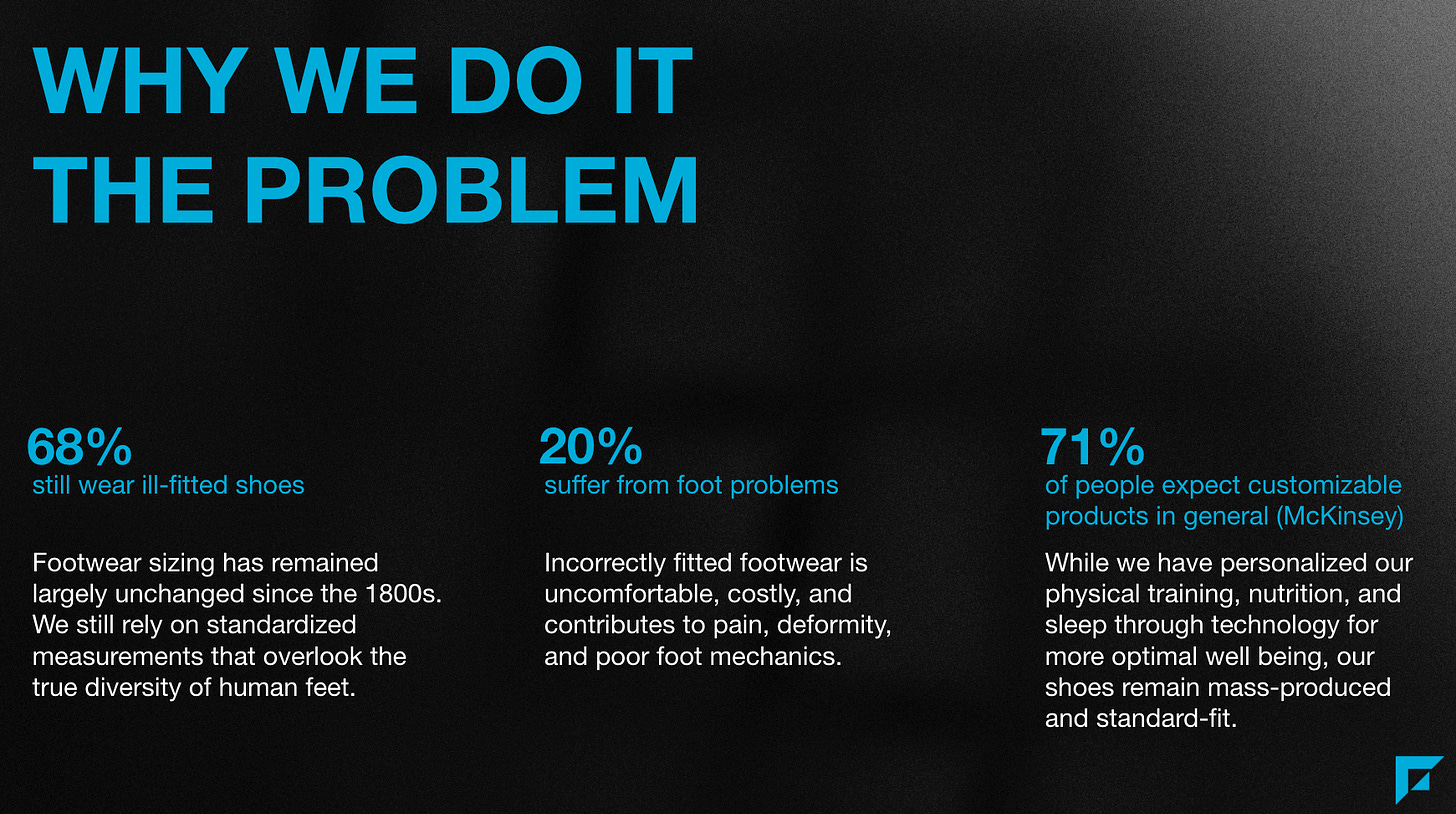

Today, as illustrated in the graph below, the footwear industry is facing a number of challenges:

Footwear sizing has remained largely unchanged since the 1800s. We still rely on standardized measurements that overlook the true diversity of human feet. Not surprisingly, 68% of people still wear ill-fitted shoes.

Incorrectly fitted footwear is uncomfortable, costly, and contributes to pain, deformity, and poor foot mechanics. As a result of that, 20% of people suffer from foot problems.

While we have personalized our physical training, nutrition, and sleep through technology for more optimal well being, our shoes remain mass-produced and standard-fit. But 77% of people expect customizable products in general, according to McKinsey.

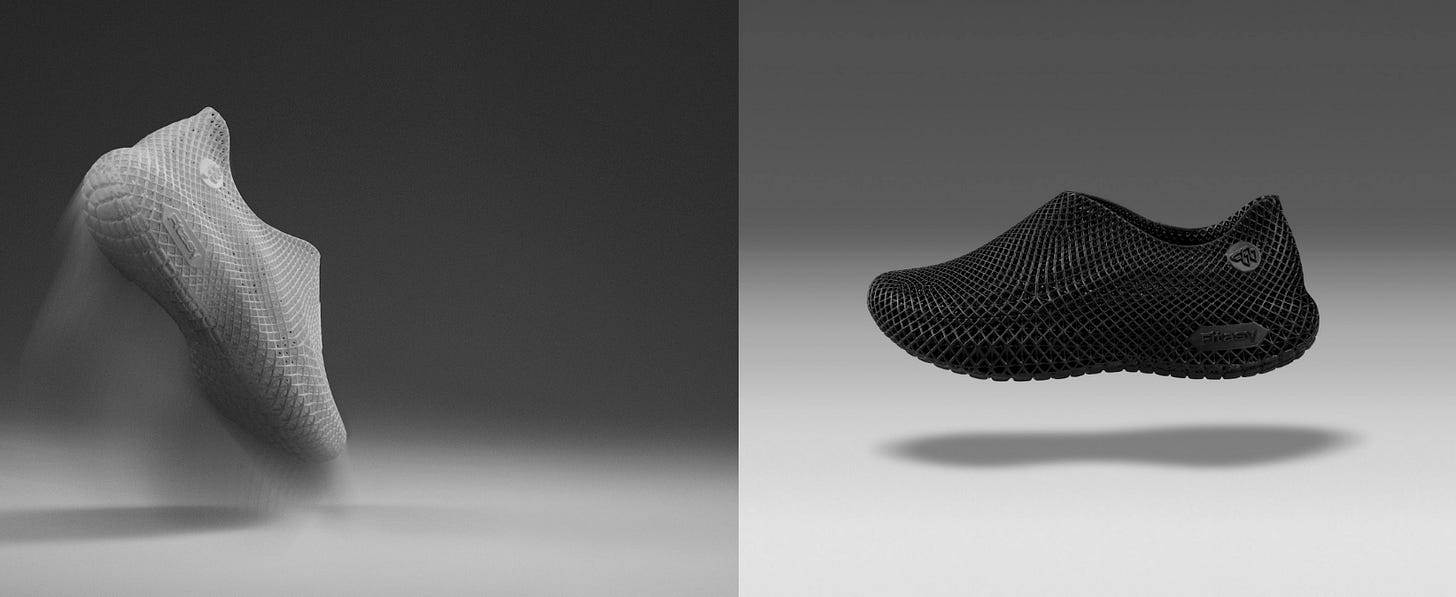

Fitasy, which aims at addressing those challenges, is a personalized footwear company focused on redefining how shoes are designed, fitted, and manufactured through data-driven customization and 3D printing. By combining mobile foot scanning technology with advanced software and engineering, Fitasy creates footwear tailored to each individual’s unique foot profile rather than relying on traditional, one-dimensional sizing systems. The brand places a strong emphasis on comfort, performance, and foot health, making its products particularly relevant for athletes and active consumers. Through a direct-to-consumer model and rapid iteration enabled by 3D printing, Fitasy aims to make high-quality, custom-fitted footwear more accessible while continuously improving fit, recovery, and long-term wearability. The company is rolling out its scan-to-print app this spring, with standard-size footwear already available for purchase via its website

Picture: Fitasy’ 3D printed shoes

You can watch the video interview below by clicking on the Youtube link. You can also listen to the audio interview by clicking on the link at the top of the page:

Here is an interview at CES explaining their technology and product:

📝Show Notes: During the interview with Kevin, we discussed his background as a lifelong athlete and how years of frustration with ill-fitting footwear led him to co-found Fitasy, a personalized 3D-printed footwear company. Kevin shared how his experience in finance and venture capital, combined with exposure to cutting-edge research from his MIT-trained co-founder, shaped his belief that footwear should be custom-fitted for every individual. He explained how Fitasy uses mobile foot scanning and data-driven 3D printing to create shoes tailored to each person’s unique foot profile, addressing long-standing limitations in traditional footwear sizing and manufacturing.

During the interview with Kevin, we also explored Fitasy’s application in elite sports, particularly as a recovery solution for athletes. Kevin highlighted the benefits of 3D-printed footwear for teams and practitioners, including improved cushioning, shock absorption, arch support, and breathability, all of which contribute to recovery, comfort, and long-term foot health. He outlined Fitasy’s competitive advantages in software, scanning accuracy, and rapid iteration, as well as its direct-to-consumer business model and current pricing. Looking ahead, Kevin shared his plans to deepen engagement with professional athletes and teams, expand product offerings, and continue refining customization through fast, athlete-driven innovation.

You can read the full transcript of the podcast interview with Kevin located at the top of this blog post.

Here are the quotes from the interview with Kevin:

1. Your background and what led you to your company

“I grew up playing a lot of sports, so I’ve always considered myself an athlete. I played national-level soccer growing up, university-level basketball, and nowadays it’s mostly club-level tennis. Over the past two decades of playing sports, footwear has always been something that troubled me. Finding the right shoe has always been difficult—different sizing systems, different brands, styles going out of line—and I think that challenge may have even hindered my ability to progress as an athlete.”

“Outside of sports, I studied finance and computer science and later worked in finance and venture capital. I saw a lot of examples where technology was reshaping very traditional industries, and that really stuck with me. When I met my co-founder Yujun, who comes from a team of research scientists at MIT, he pitched the idea of using a phone as a scanner to reduce online footwear returns caused by poor fit. That was the moment I realized that in the future, every shoe should be custom-fitted for the customer.”

2. Overview of the product

“At its core, Fitasy is a 3D-printed footwear company. We use 3D printing because it allows for a much more data-driven approach and a much higher level of customization. On paper, we make footwear that can come in standard sizes, but more importantly, it can also be custom-fitted for each individual based on their unique foot profile.”

“The process starts with mobile scanning. Any user with an iPhone can scan their foot using our app, and the whole process takes about two minutes. We analyze that data to create a foot profile, feed those parameters into our system, and then send it to production. The printing itself takes about four to five hours, and with post-processing and packaging, the shoe is typically ready to ship within three to four days.”

3. Main use cases for elite sports

“The fundamental philosophy behind our brand is that the foot is incredibly unique and very complex, but in today’s world it’s mostly treated as a single factor—length. That’s essentially how footwear sizing has worked since the 19th century. In elite sports, athletes exert so much energy on the court or on the field, but off the court we often neglect how they treat their feet.”

“What we’ve found is that 3D printing allows us to create an excellent recovery shoe. We can design superior cushioning compared to traditional foam materials, while also embedding breathability and arch support directly into the structure of the shoe. That combination is particularly valuable for elite athletes.”

4. Benefits for practitioners and teams

“A good recovery shoe needs a few core features. First is cushioning, because all the impact from the ground shouldn’t transfer directly into the muscles and joints. Then there’s arch support, which helps create a more balanced pressure distribution across the foot so muscles don’t fatigue as quickly.”

“Breathability is also critical. Feet sweat a lot, and in unbreathable environments fungus can grow, which is why problems like athlete’s foot are so common. Because of the 3D-printed structure, our shoes naturally provide excellent shock absorption, airflow, and support, making them especially effective for recovery in high-performance environments.”

5. Competitive advantages

“3D printing itself isn’t proprietary—anyone with a printer can print something. Our competitive advantage really comes down to two things. The first is mobile scanning. Customization only works if the foot data is accurate. If you can’t scan the foot accurately, everything else becomes pointless.”

“We developed our own scanning solution and algorithms to ensure high accuracy, currently within about two to four millimeters. The second advantage is what we do once we have that data—how we build the 3D model, design the lattice structure, and customize the shoe specifically for each foot profile. That software-first approach is what really sets us apart.”

6. Current business and pricing model

“Our business model is direct-to-consumer. Everything happens through our website. Customers choose a product, select the custom-fit option, and once they place an order, we send them an invitation link to download the app and submit their foot scan. After that, they just wait for their shoes to be produced and delivered.”

“Right now, our pricing is just over $200, typically around $210 to $220. It’s not a cheap shoe by any means, but from a customization perspective, it’s a strong value proposition. As printing efficiency improves and material costs come down, we expect to be able to lower prices over time.”

7. Plans and aspirations for the next 12 months

“Over the next 12 months, we’re really focused on engaging more with athletes and communities that care deeply about foot health, longevity, and quality of life after their playing careers. We’re currently working with an MLS team and have received very positive feedback, which tells us we’re solving a real problem.”

“One of the biggest advantages of 3D printing is speed. Compared to traditional mold-based manufacturing, which is slow and expensive, we can iterate very quickly. If athletes tell us they need better arch placement or a different shape, we can bring those changes to life fast. This year, we’re planning to release several new products so people can experience different levels of customization.”

You may also like: